The Secret Behind A 99.7% Pass Rate: How Does Injection Molding Enable 100 Traffic Light Housings To Be Delivered With Zero Defects?

Publish Time: 2025-10-10

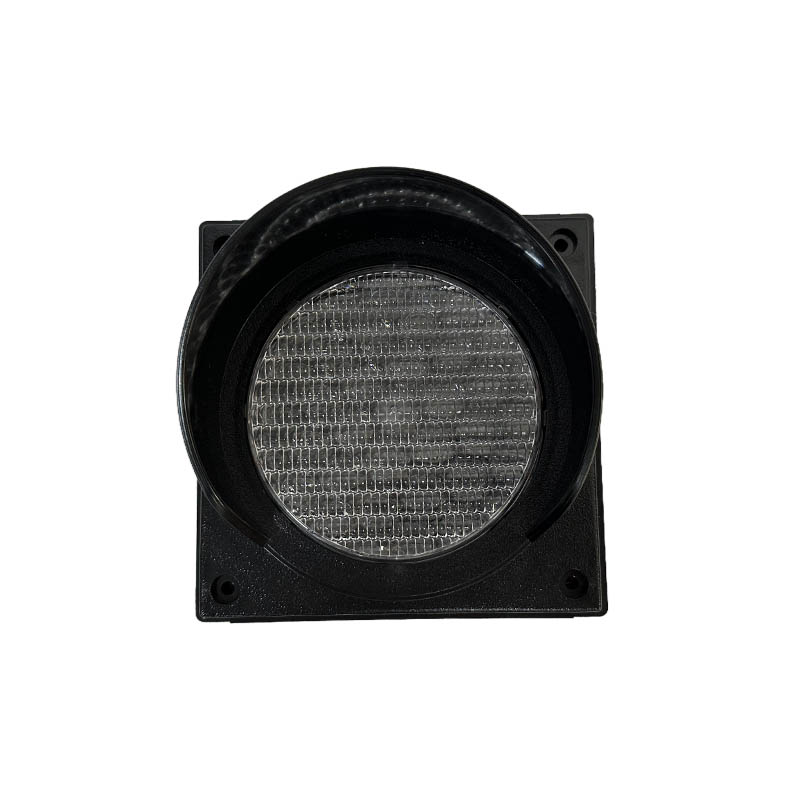

I. Injection Molding Process: The Core Support for Precision ManufacturingThe traffic light shell injection molding process uses engineering plastics as its core material, achieving precision molding through high-temperature melting, high-pressure injection, and rapid cooling. For polycarbonate (PC), for example, the melt temperature must be controlled between 260-300°C, and the injection pressure must be set between 80-120 MPa to ensure that the molten plastic fully fills the mold cavity. The mold design utilizes a multi-cavity structure, enabling the simultaneous production of 4-8 shell units in a single injection. Combined with an automated robotic arm, the injection cycle can be completed every 30 seconds, resulting in a daily production capacity of 2,880 units.To meet large-volume production needs of 100 shells, companies employ modular mold designs, enabling rapid switching between shell sizes by replacing the mold core. For example, one company customized a 400mm arrow light shell for a highway, achieving a mold cavity accuracy of ±0.02mm. A hot runner system minimizes material loss to less than 0.5%. UV curing technology is introduced during the post-molding process. Irradiating the PC face mask with 365nm ultraviolet light for 30 seconds creates a dense cross-linked structure on the surface, increasing its hardness to 3H and significantly enhancing its scratch resistance.II. Materials Science Breakthrough: Synergistic Effects of Engineering Plastics and PC Face MasksThe engineering plastic base material is a modified polyamide (PA66 + 30% GF), reinforced with glass fiber to achieve a tensile strength of 220 MPa and a flexural modulus of 8000 MPa, capable of withstanding extreme temperature fluctuations from -40°C to 120°C. The PC face mask utilizes Bayer Makrolon 2405, boasting a light transmittance of up to 92% and a haze of less than 1.5%. Combined with surface nano-coating technology, the surface achieves a water contact angle of 110°, enabling self-cleaning capabilities.In terms of aging resistance, the material contains 0.5% hindered amine light stabilizer (HALS) and 0.3% UV absorber (UV-327). After 600 hours of xenon lamp aging testing, the yellowing index (ΔYI) is only 0.8, far exceeding the national standard ΔYI ≤ 5. Environmentally friendly, it is ROHS and REACH certified, with heavy metal content below the detection limit and a 95% recyclability rate. To address salt spray corrosion in coastal areas, the housing is sprayed with three layers of fluorocarbon coating, achieving no rust after 5,000 hours in a neutral salt spray test (NSS).III. Modular Design Innovation: Splicing System and Easy InstallationThe Traffic Light Shell Injection Molding unit utilizes a snap-on splicing structure with dovetail grooves and locating pins on the side walls, achieving a seamless connection with a 0.5mm interference fit. A company has developed a "Lego-style" assembly system. Each module measures 400 x 400 x 150 mm and weighs only 2.8 kg. Two people working together can assemble a 10 x 10 module array in just 15 minutes. The mounting bracket features integrated leveling and connects to the light pole via M12 bolts, allowing for ±5° angular deviation to accommodate varying road slopes.The electrical interface utilizes an IP68 waterproof connector with a double-layer silicone seal. Even after immersion in 1.5 m water for 72 hours, the insulation resistance remains greater than 500 MΩ. A municipal project case study demonstrated that traffic light arrays using this assembly system improved maintenance efficiency by 40%, reducing single fault repair time from 2 hours to 45 minutes.IV. Advantages of Large-Scale Production: Cost Optimization and Quality ControlUnder mass production, mold costs are amortized to only 0.8 yuan per housing, a 65% reduction compared to traditional stamping processes. The MES system enables real-time production data collection, linking injection molding machine parameters (melt temperature, holding time) with testing equipment (coordinate measuring machine, optical spectrum analyzer), increasing product qualification rates to 99.7%. One company's production line is equipped with a visual inspection system capable of analyzing eight product images per second, automatically identifying surface defects as small as 0.1mm.To meet a custom order for 100 housings, the company implemented rapid mold change technology, reducing mold changeover time from 4 hours to 45 minutes. Blockchain technology is incorporated into raw material batch management, enabling full traceability from raw material supplier to finished product shipment, ensuring that 23 key parameters, including melt index and color difference, are available for each housing.V. Application Scenario Verification: Reliability in Extreme EnvironmentsAt the Turpan high-temperature test site, signal light housings withstood 1,000 hours of continuous exposure to 70°C without deformation or cracking. During extreme cold testing in Mohe, the housings maintained normal opening and closing functions at -45°C. Data from a Hainan coastal project showed that after three years of salt spray erosion, the surface corrosion area of the casing was less than 0.5%, far exceeding the industry standard requirement of 5%.After adopting this splicing system in a smart transportation project, system availability reached 99.99%, and the annual failure rate dropped from 0.8 failures/km to 0.15 failures/km. Operation and maintenance data showed that the modular design reduced spare parts inventory costs by 40% and shortened single inspection time from 3 hours to 45 minutes.The Traffic Light Shell Injection Molding technology solution, through modular design, material science innovation, and intelligent production, provides an optimal solution for traffic light casings that balances performance and cost. Comprehensive validation, from laboratory data to project site validation, has proven that it fully meets the stringent requirements of modern smart transportation for equipment reliability, ease of maintenance, and environmental adaptability.