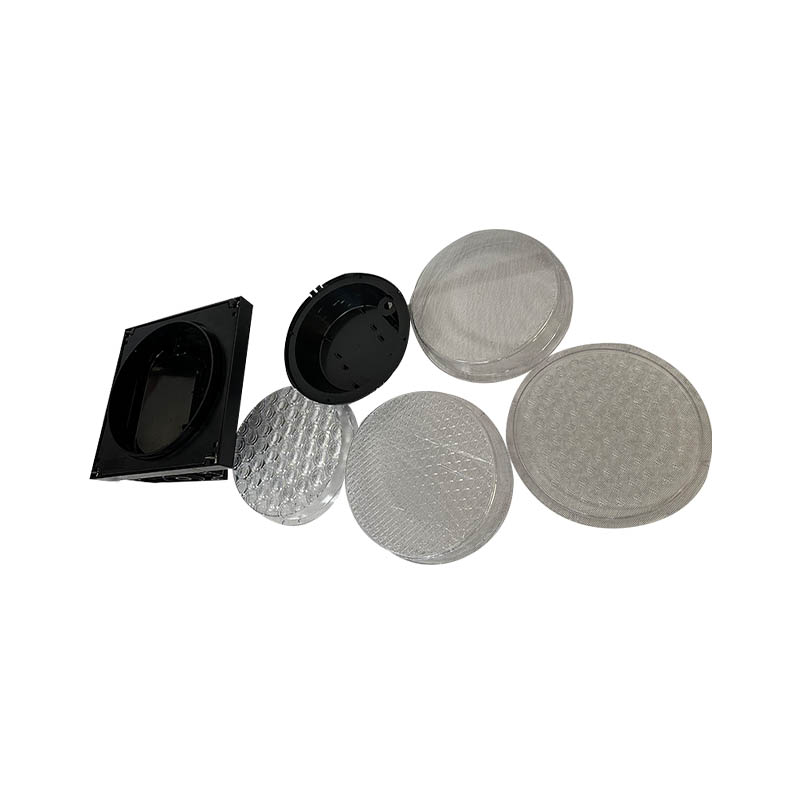

Controlling gate marks in traffic light shell injection molding is a systematic engineering process involving design, process, mold and materials.

- +86-13480505563

- 664019397@qq.com

- No. 2 Minfu Road, Shatou Industrial Zone, Shajing Town, Bao'an District, Shenzhen City, Guangdong Province